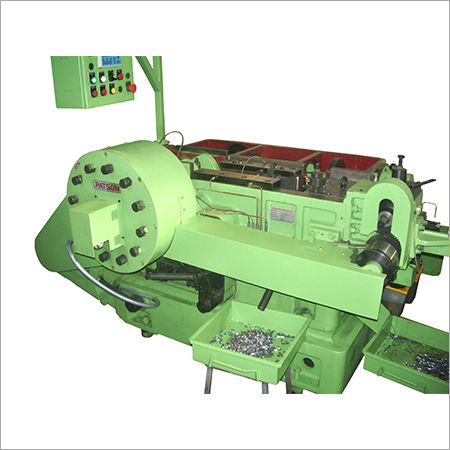

Bullet Lead Swaging Machines

Product Details:

- Lubricating System Centralized Automatic

- Production Capacity 5000-10000 bullets/hour

- Noise Level 75 dB

- Operating Temperature 0-45C

- Motor Power 7.5 kW

- Drive Hydraulic Drive

- Machine Type Hydraulic Swaging Machine

- Click to view more

Bullet Lead Swaging Machines Price And Quantity

- 9000000 INR/Unit

- 1 Unit

- Approx. 8 kW/h

- Every 500 hours

- Automatic Vibratory Feeder

- 0.177 to 0.50 inches

- 4-6 Bar (for auxiliary functions)

- 70% RH

- 5-10 minutes

- High Speed Tool Steel

- Available

- Automatic emergency stop, overload protection

- Touchscreen HMI

- 120 cycles/minute

Bullet Lead Swaging Machines Product Specifications

- Hydraulic Drive

- 7.5 kW

- 0-45C

- Automatic Water-Cooling

- Hydraulic Swaging Machine

- 1 year

- Powder Coated

- 7.5 kW

- 75 dB

- 5000-10000 bullets/hour

- Lead bullet swaging for ammunition manufacturing

- 2500 mm x 1200 mm x 1800 mm

- Automatic

- 30-50 Ton (Adjustable)

- Centralized Automatic

- Ethernet, USB for data logging

- Heavy Duty Welded Frame

- 415 V

- 50 Hz

- Electricity

- apple green

- 1500 kg

- 0.05 mm

- PLC Control Panel

- Cutting Machine

- Swaging Automation

- 7.5 kW 10 HP

- High efficiency, robust construction, easy maintenance, safety interlocks

- BLSM-5000A

- Approx. 8 kW/h

- Every 500 hours

- Automatic Vibratory Feeder

- 0.177 to 0.50 inches

- 4-6 Bar (for auxiliary functions)

- 70% RH

- 5-10 minutes

- High Speed Tool Steel

- Available

- Automatic emergency stop, overload protection

- Touchscreen HMI

- 120 cycles/minute

Bullet Lead Swaging Machines Trade Information

- 4 Unit Per Year

- 24 Week

Product Description

Bullet Lead Swaging Machines

Our bullet lead swaging machines ensure precision, mass production and quality. Keeping the hose application in mind, we offer the right swaging solution as per exact specifications.The machines are applicable in bullet product lines. Swaging machines perform with dies. The swaging illustrate the process of bullet. It is usually a cold working process. Our machines are engineered for accuracy and complete traceability. They well configure, repeat and control the pressure.

https://www.youtube.com/watch?v=LnrCT8zwxBw

Technical specification

|

Machine |

Bullet Lead Swaging Machines - Model 539 |

|

Component |

Lead Slug- caliber 5.56/7.62/9 mm. |

|

Operation |

Cutting & Swaging for profile |

|

Cycle Time(Output/hr.) |

150 per Min.(9000/hr.) |

Precision Swaging for Diverse Applications

Featuring adjustable die settings and automatic feeding, this swaging machine delivers consistent bullets across a wide diameter range. Its robust construction and cutting-edge components make it ideal for manufacturers seeking high throughput and minimal changeover downtime.

Advanced Safety and User Interface

Operator security is prioritized with automatic emergency stop and overload protection systems. The touchscreen HMI simplifies operation, allowing users to monitor performance, adjust parameters, and streamline production processes for maximum efficiency.

Efficient Operation and Maintenance

Designed for continuous use, the machines maintenance interval is set at every 500 hours, ensuring reliable output. Rapid changeover capabilities enable swift adaptation to different bullet sizes, while installation and technical support are readily available for seamless setup.

FAQs of Bullet Lead Swaging Machines:

Q: How does the automatic vibratory feeder improve the bullet production process?

A: The automatic vibratory feeder consistently supplies lead to the swaging unit, eliminating manual handling and reducing downtime. This ensures smoother, uninterrupted operation and uniform feeding for precise bullet formation.Q: What are the benefits of using high speed tool steel dies in this machine?

A: High speed tool steel dies provide enhanced durability and wear resistance, extending service life and maintaining consistent bullet dimensions even under rigorous production cycles.Q: When should maintenance be performed on the Bullet Lead Swaging Machine?

A: Routine maintenance is recommended every 500 operating hours to sustain optimal performance, prevent unexpected breakdowns, and ensure the safety features and mechanical components function reliably.Q: Where can the Bullet Lead Swaging Machine be installed, and is installation service available?

A: The machine can be installed in manufacturing environments with ambient humidity up to 70% RH and access to electricity and compressed air (46 Bar). Professional installation service is available to ensure proper setup and operation.Q: What safety mechanisms are integrated into the machine for operator protection?

A: Key safety features include an automatic emergency stop and overload protection, which safeguard operators by shutting down the machine instantly in case of mechanical or electrical fault.Q: How quickly can bullet diameter changeovers be performed?

A: Diameter changeovers can be completed within 5 to 10 minutes, enabling rapid adaptation to different bullet specifications and minimizing production interruption.Q: What advantages does the touchscreen HMI provide to users during machine operation?

A: The touchscreen HMI offers intuitive controls for process monitoring, parameter adjustment, and troubleshooting, making machine operation user-friendly and efficient for operators with varying levels of technical expertise.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+