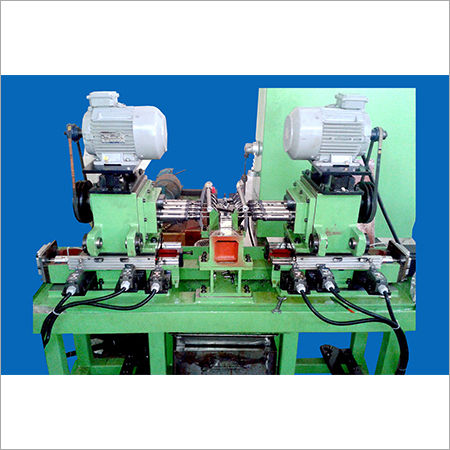

Three Way Drilling Machine

Product Details:

- Features High Precision

- Diameter 3 mm - 50 mm (Drilling Range) Millimeter (mm)

- Condition New

- Product Type Industrial Drilling Machine

- Material Mild Steel

- Automatic Grade Automatic

- CNC Or Not CNC

- Click to view more

Three Way Drilling Machine Price And Quantity

- 1 Unit

- 2600000.00 INR/Unit

Three Way Drilling Machine Product Specifications

- High Precision

- 3 HP - 10 HP Horsepower (HP)

- Electric

- Metal Drilling, Plastic Drilling, Automotive & Engineering Industries

- CNC

- Industrial Drilling Machine

- 210-230 V Volt (v)

- New

- 3 mm - 50 mm (Drilling Range) Millimeter (mm)

- 1200 * 900 * 1600 mm (Approx.) Millimeter (mm)

- Automatic

- Green

- Mild Steel

Three Way Drilling Machine Trade Information

- 10 Unit Per Month

- 10-12 Week

Product Description

Leveraging on our years of experience in this industry, we are highly reckoned for manufacturing and exporting an excellent quality Three Way Drilling Machine. Widely used in engineering, automobile, metal working and other manufacturing industries for drilling work, these machines are manufactured in strict tandem with industry standards. Integrated with advanced technique for steady performance, this Three Way Drilling Machine is inspected on various standard quality parameters.

The three way drilling machines fall into the category of advanced industrial machinery, as they are designed to perform the drilling operations from three sides in a simultaneously. Therefore, these machines guarantee higher accuracy and uniformity with increased production efficiency. These machines have wide applications in metalworking, fabrication, and manufacturing units that require drilling with high precision and repetition. With strong structures, adjustable spindles, and smooth controls for operation, they save human effort and reduce production time. Multiple drill sizes are also supported by three-way drilling machines, which make them ideal for complicated parts and heavy-duty applications. Their power-packed performance and reliability make them a demanded choice for high-volume machining processes.

Features of Three Way Drilling Machine:

- Can bear heavy load

- Robust construction

- Reduced downtime

Specification of Three Way Drilling Machine:

Machine Three Way Drilling Machine - Model 888 Component Front Axle Support Operation Drilling Cycle Time(Output/hr.) 120 sec.(30/hr.)

FAQs of Three Way Drilling Machine:

Q. What is a three way drilling machine?

Q. Where are three-way drilling machines normally used?

Q. What are the primary advantages of the three-way drilling machine?

Q. Are three-way drill machines capable of handling various sizes of drills?

Q. What maintenance do three way drilling machines need?

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+